Process synergy, quality without any compromise.

Every single phase of our process is internal and perfectly monitored by a staff equipped with the most advanced technologies. Product and process travel on parallel tracks.

We can import the native 3D files from CATIA and NX and we design our moulds with VISI by Hexagon.

A cooperative attitude in terms of co-engineering supports our Customers in the realization of the best product.

Process synergy, quality without any compromise.

Every single phase of our process is internal and perfectly monitored by a staff equipped with the most advanced technologies. Product and process travel on parallel tracks.

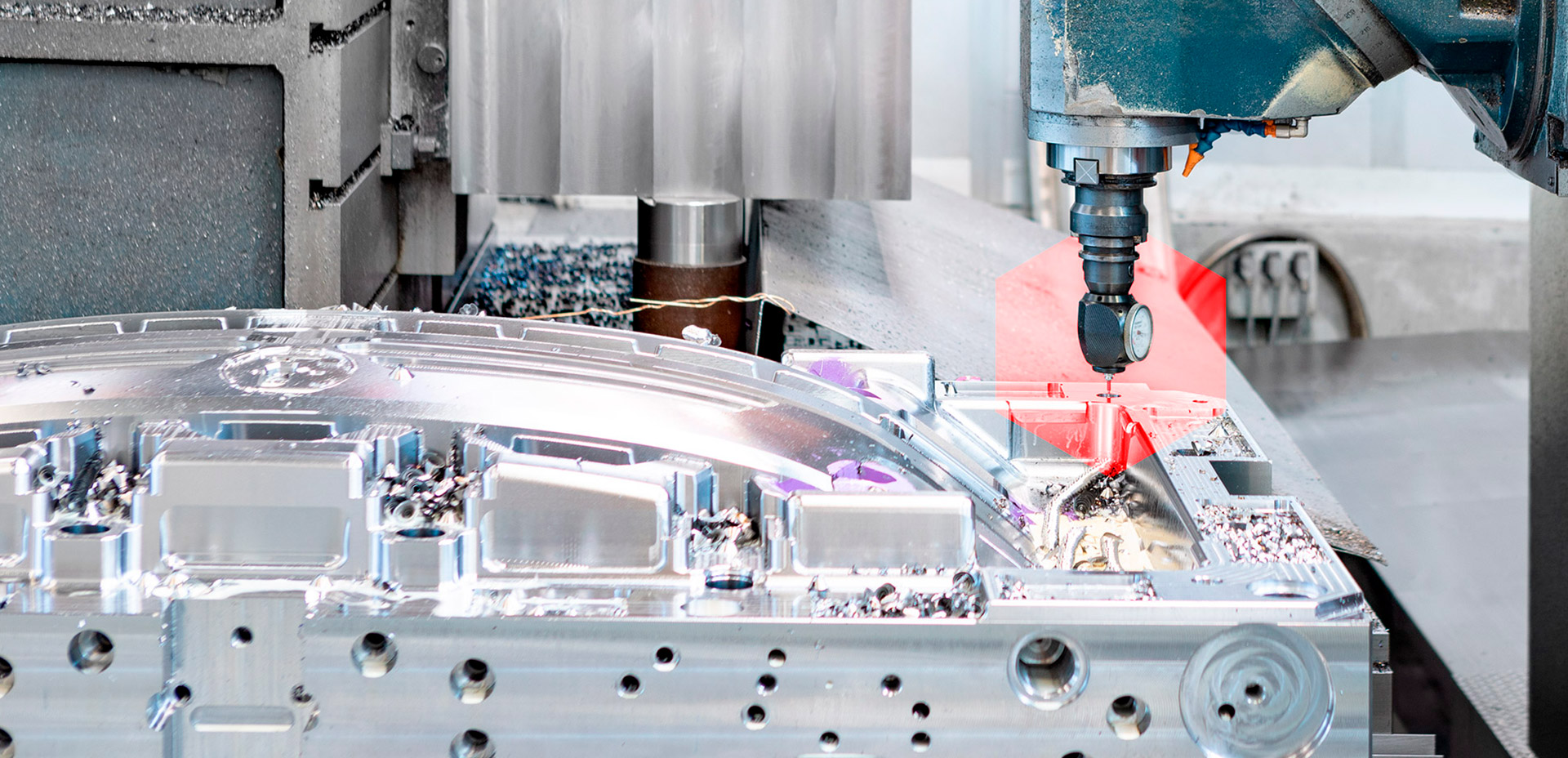

Manufacturing

At the heart of our operating structure there are powerful entrepreneurial culture and a continuous research of new technologies that can always help to improve the quality of our works.

Machinery park

| Type of machine | Nomination | Specification | |

| MILLING | PARPAS | DIAMOND 30 | Dimension 2800x3100x1200 |

| MILLING | PARPAS | DIAMOND 45 | Dimension 2200x1500x1000 |

| MILLING | PROMAC | VTR/D | High speed - 5 axes - dim. 1600x1000x800mm |

| MILLING | MAKINO | D500 ROBOT 3 R | High speed - 9 pallets - 5 axes - dim. 550x1000x500mm |

| MILLING | PARPAS | XS | Dimension 6000x3000x1500mm |

| MILLING | SACHMANN | TRT | Dimension 3000x2000x1600mm |

| MILLING | PARPAS | LHS | High speed - dim. 3000x2000x1200mm - 5 axes |

| MILLING | PARPAS | ML90 | 6 axes - dimension 6000x2000x1250mm |

| MILLING | FANUC | ALFAT 14ic | High speed - size 500x350x400mm |

| DRILLING | IMSA | MF 1200 BBLL | 7 axes |

| EDM | INGERSOLL | 1500 | Internal dimension 2520x1520x945mm |

| EDM | FANUC | ALFA 1A | With cutting thread (wire erosion) |

| SPOTTING MACHINE | MILLUTENSIL | MIL 263 | |

With the most updated technologies our projects run 24/7.

We constantly carry out inspections and dimensional measurements to monitor each manufacturing phase.

The support of a management software completely integrated with the production assures the organization of the customized warehouse for each Customer’s project, providing speed and efficiency during the assembling phase.

Regro has been building over the years an important collaboration network with suppliers that support us in the trials of our moulds.